STATE-OF-THE-ART

RESEARCH & DEVELOPMENT

Empowering quality, safety, and innovation through cutting-edge R&D and material science.

Driving Innovation:

The Strength of Our R&D Team

At Wellcall, innovation is at the heart of everything we do. Our in-house R&D division plays a crucial role in developing high-performance rubber hose solutions that meet the evolving needs of global industries.

With a team of experienced engineers and materials scientists, we continuously explore new technologies, rubber compounds, and design improvements to deliver exceptional hose durability, flexibility, and safety.

Our R&D process is fully integrated into our product development lifecycle—ensuring every product we launch is engineered to exceed international standards.

From prototype testing to advanced simulations, we adopt a data-driven, customer-focused approach to ensure our hoses perform in the most demanding environments.

At Wellcall, innovation is not a department — it’s a mindset embedded across the entire organization.

Our Internal Laboratory

Our ISO-certified Central Laboratory is equipped with state-of-the-art testing equipment to evaluate hose quality, strength, and chemical resistance.

Every batch is rigorously tested to maintain consistency and compliance with global industry benchmarks.

Laboratory & Facilities

We continuously upgrade our research laboratory and facilities to further enhance our product quality, features, performance and also liability. Below are some of the facilities involved:

Insulative Tester

Tests electrical insulation properties and dielectric strength of rubber materials.

Rheometer

Tests electrical insulation properties and dielectric strength of rubber materials.

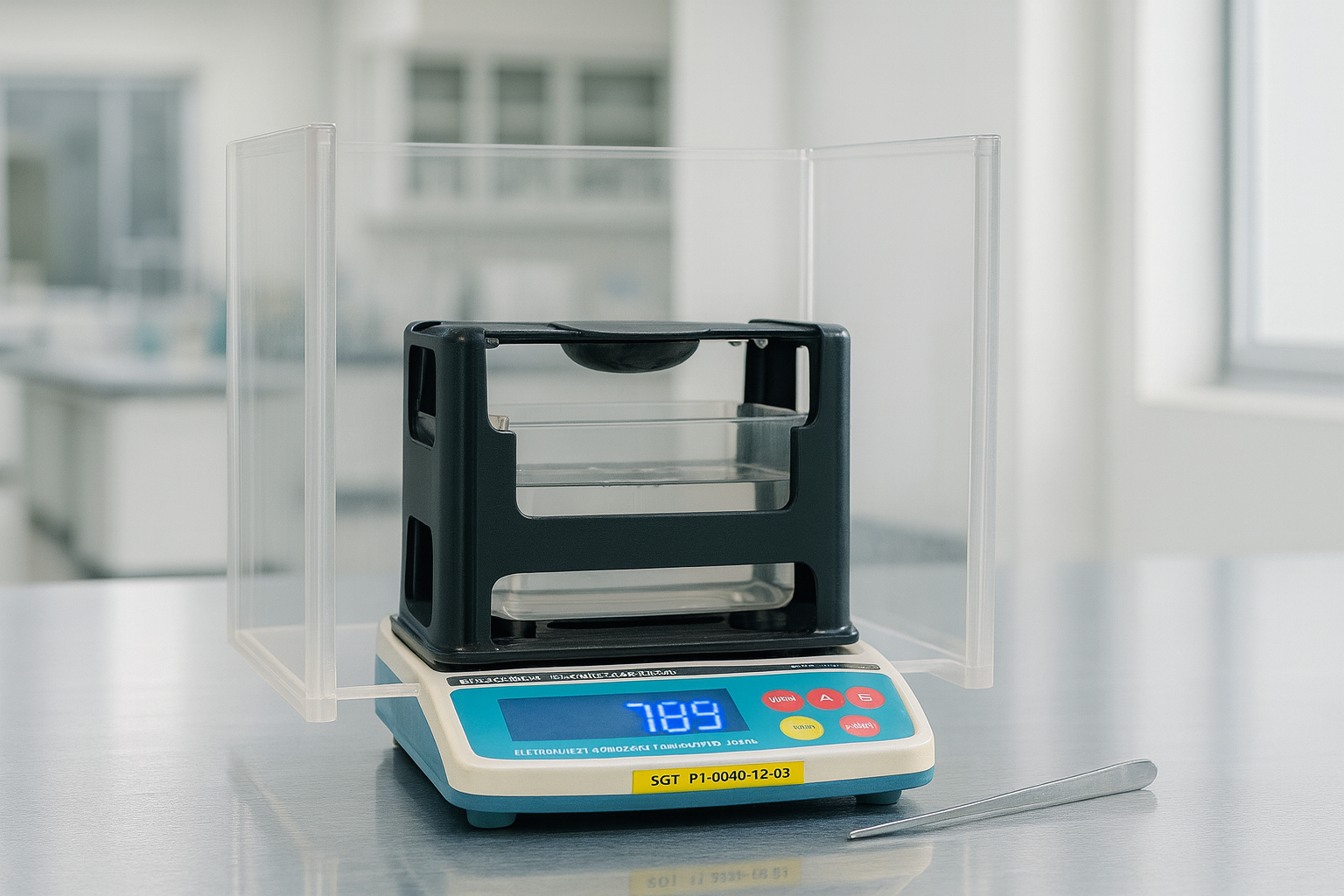

Specific Gravity Meter

Measures the density and specific gravity of rubber compounds.

Ozone Chamber

Tests rubber resistance to ozone cracking and environmental degradation.

Tensile Testing Machine

Measures tensile strength, elongation, and modulus of rubber materials.

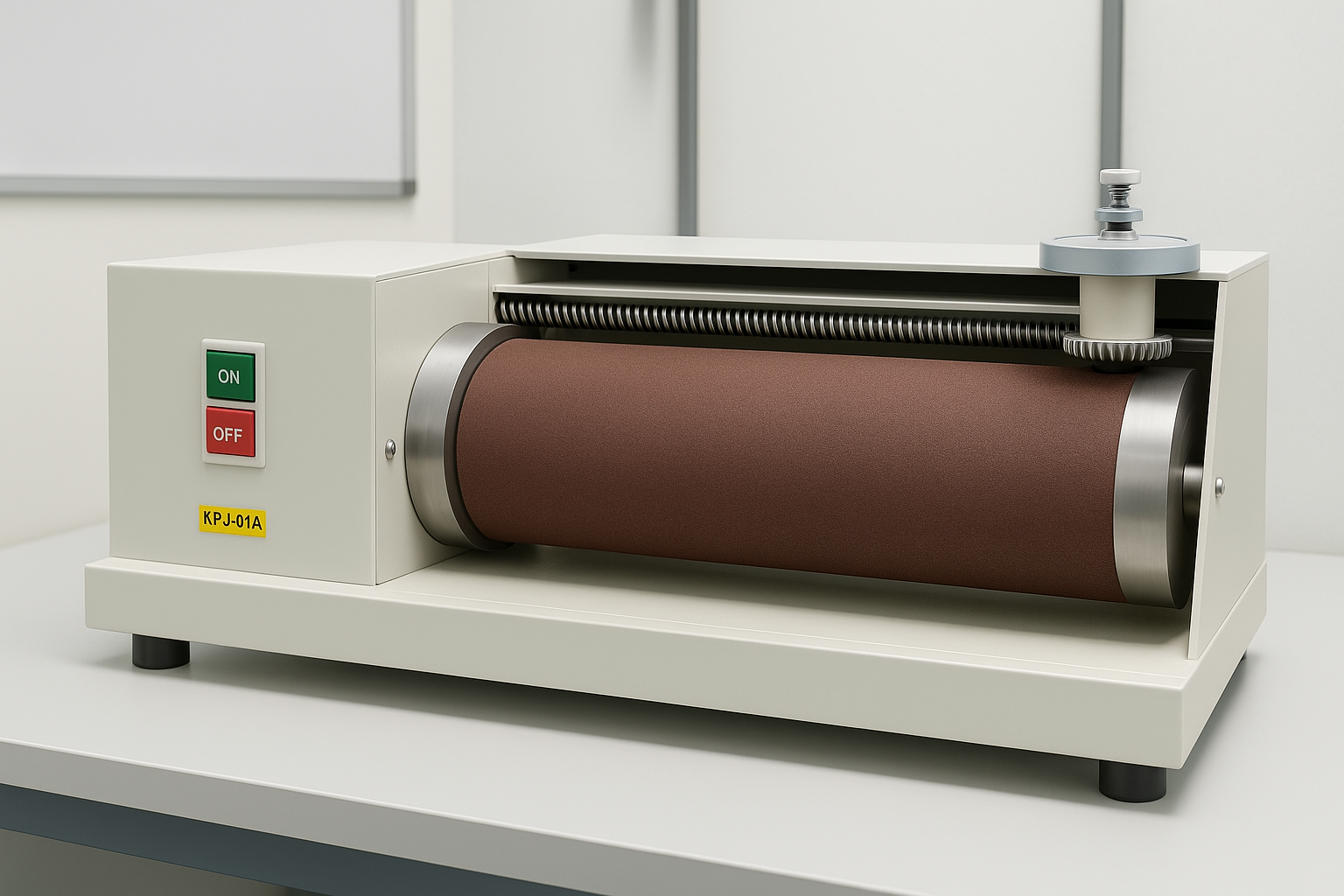

Abrasion Tester

Evaluates the wear resistance and abrasion properties of rubber materials.

Aging Oven

Simulates accelerated aging to evaluate long-term performance of rubber materials.

Hardness Meter

Determines the hardness of rubber compounds using Shore A and D scales.

Low Temperature Chamber

Tests rubber performance in extreme cold conditions and low-temperature flexibility.

Mooney Viscometer

Measures the viscosity of rubber compounds to ensure consistent processing.

Moulding Press Machine

Creates test specimens and simulates production processes for rubber compounds.

Quality Assurance Standards

Our commitment to quality is reflected in our adherence to international standards and rigorous testing protocols. Every rubber hose that leaves our facility has undergone comprehensive testing to ensure it meets or exceeds industry requirements.

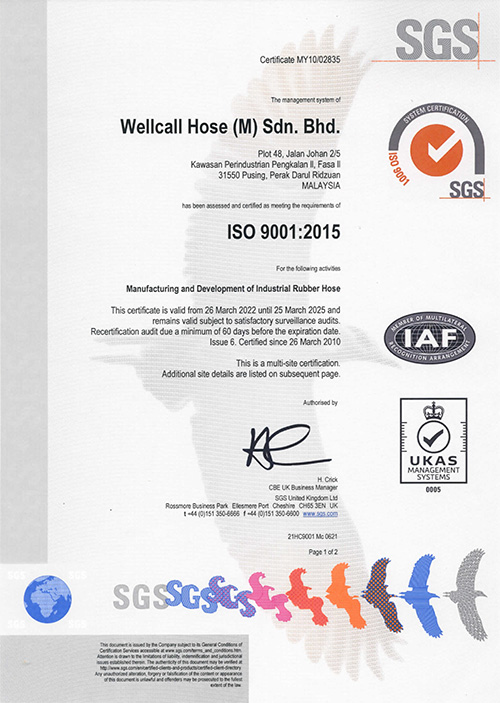

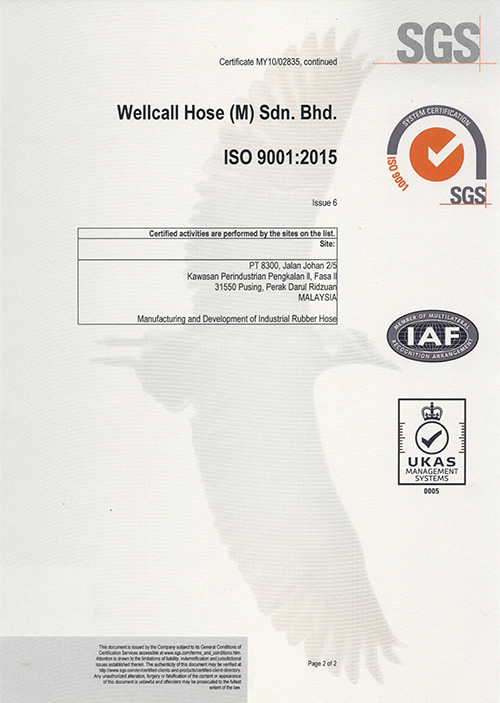

ISO 9001:2015 Certified

Our quality management system is certified to ISO 9001:2015, ensuring consistent quality across all our processes and products.

ISO 9001:2015 Certified

Our quality management system is certified to ISO 9001:2015, ensuring consistent quality across all our processes and products.

Industrial Hose Standard Compliance

Our hoses comply with internationally recognized standards to ensure reliable performance across diverse industries. Each product is tested and certified to meet regulatory and customer-specific requirements.

Certifications & Affiliations

As a globally trusted hose manufacturer, Wellcall holds certifications from SIRIM, SGS, and other leading quality assurance bodies. These accreditations reinforce our commitment to safety, performance, and environmental compliance.